The Linen Lab is a leading linen fabric producer

From the day The Linen Lab was founded in Seoul, South Korea, in 1987, under the name of Lino, we have been producing one of the highest quality linen fabrics on the market. We offer classic designs, as well as unique and experimental fabrics. Most of our linen fabrics are produced in small numbers and are not likely to be restocked once sold out. That’s why The Linen Lab’s linen fabrics are unique and exclusive to our website. In addition to quality control, our goal is to maintain sustainability. We use eco-friendly materials and methods to prioritize minimizing waste in the production process. We hope that our small actions can reduce our environmental impact. Thankfully, people have responded positively to our initiatives. We now have customers not only from Korea’s well-known brands but also from all over the world.

Since our linen fabrics are not mass-produced and are most likely never to be made again once they sell out, The Linen Lab’s linen fabrics are unique and exclusively sold on our website.

Our Founder, Mr.Bongjo Ahn

Our story began with our founder, Mr. Bongjo Ahn. For 25 years, he worked in spinning and weaving mills, achieving success in various fields of the textile industry. In the 1980s, linen fabrics began to gain popularity worldwide. Recognizing the potential of linen, he established Lino in 1987, which became The Linen Lab we know today. Even after four decades, Mr. Ahn remains a guiding force for the company. He shares his insights and continues to play a crucial role in The Linen Lab office. We uphold his legacy of dedication and standards for excellence.

1987-1999

After Lino was established in 1987, our founder collaborated with Daenong, a prominent spinning and weaving company from Korea’s 1970s and 1980s, to develop 100% linen and linen-rayon yarns. He played a key role in popularizing linen fabrics in Korea by partnering with various weaving and dyeing mills in Daegu. While Korea's textile industry was thriving, Lino focused on mass-producing linen fabrics that were easier to manufacture.

Looking Ahead

Finding high-quality linen fabrics of various types can be challenging for the average consumer. We are committed to offering these linen fabrics at affordable prices.

HOW THE LINEN LAB’s FABRICS ARE MADE

Textile Design

The Linen Lab’s fabrics are unique because we design the fabrics ourselves. This process allows us to adjust thread thickness and shapes, enabling us to create various weaves and patterns. It also lets us check for any issues in the layout and structure of the designs.

Handloom

One reason our linen fabrics are of such high quality is our meticulous attention to detail, including the use of handlooms. These small, manually operated weaving machines allow us to inspect fabric patterns, thickness, size, color, and design, as well as the weaving structure. This allows us to prevent potential issues before the main production begins.

Yarn Dyeing

Since The Linen Lab produces a significant amount of yarn-dyed fabrics, we conduct experiments to achieve precise thread colors and collect data in the process. Selected threads undergo dyeing in high-pressure, high-temperature machines and are subsequently rewound before being sent to the weaving mill.

Production Request

Even with the widespread use of AI and digital processes, we have maintained the tradition of using analog forms from the 1980s for production orders. The analog approach helps us decide on thread types, verify dye data, and assess arrangements, density, and fabric structure. This approach ensures precise and informed orders based on our accumulated expertise.

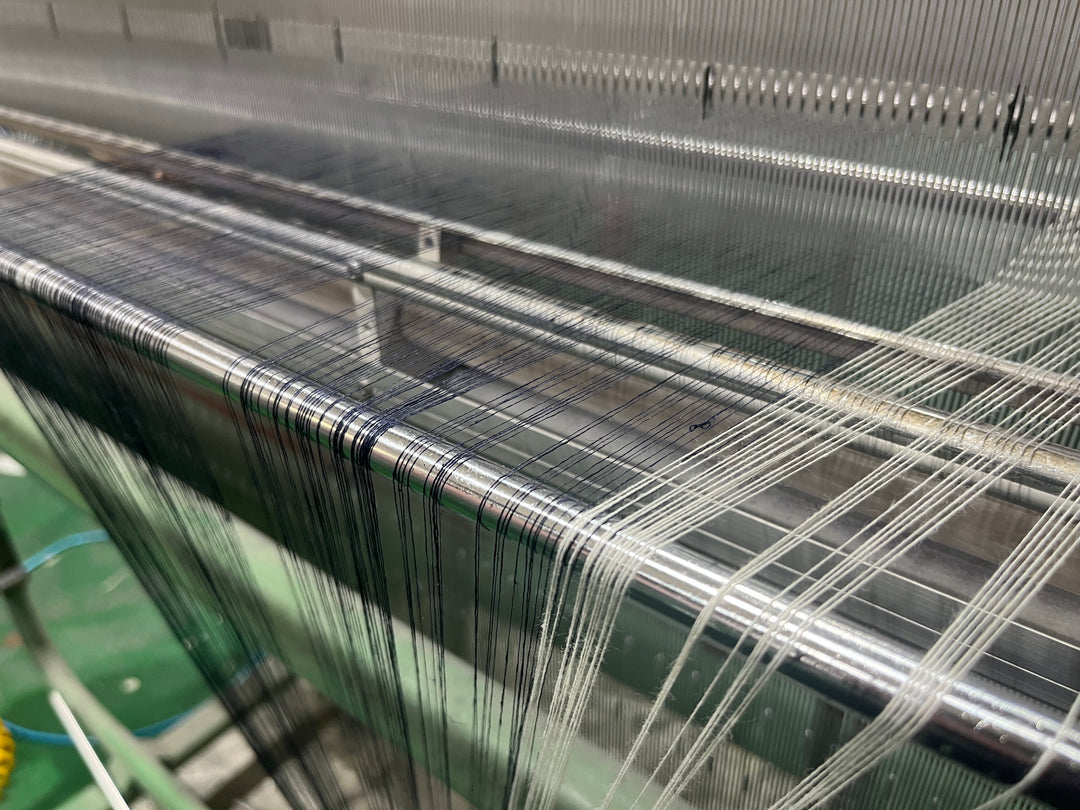

Warping

Warping is the first stage of weaving. Before it starts, our warping factory meticulously sorts and arranges the yarns. During the process, precise tension adjustment is essential for each yarn type. This delicate task requires attention, as even minor errors can affect fabric quality. We dedicate our expertise to this step.

Weaving

Weaving plays a crucial role in fabric production, so we rely on a skilled textile factory to handle this process. Before it starts, our producing team conducts a meticulous inspection of the yarns on the warp beam to ensure the production of high-quality linen fabrics. This attention to detail guarantees our fabrics meet the standards of excellence.

Fabric processing

Fabric processing involves scouring and—when necessary—de-sizing, bleaching, and mercerization processes. Once these meticulous steps are completed, the fabric is dried and ready to be made into high-quality linen fabrics.

Piece Dyeing

Unlike yarn dyeing, piece dyeing involves dyeing fabrics after they have been processed as a whole. We prepare the fabric and load it into the dyeing machine. After dyeing, we rinse the fabric (soaping), followed by drying. Once dried, we fold and prepare the fabric for the final step.

Fabric Pre-washing

Without additional washing, fabrics tend to be stiff and uneven. To address this, we perform a fabric washing process to soften the fabrics, ensure stable shrinkage, and remove impurities. During this process, the fabrics are rinsed, treated with fabric softener, and dried in a tumble dryer.

Mending

Linen yarn often contains numerous neps and slubs, which can significantly affect fabric quality if excessive. At The Linen Lab, we meticulously mend neps, slubs, and other fabric imperfections by hand to ensure we deliver high-quality linen that inspires your creativity.